Ihre Kommentare

Hallo,

Sie können mittels eigener C#-scripte für sich selbst eine solche Automatisierung schaffen. An Kunden können sie dies so nicht rausgeben, da diese dann ebenfalls eine Unity und game4automation Lizenz benötigen. Wenn sie ihre Anwendung als Build rausgeben benötigt ihr Kunde keine Lizenzen, allerdings müssen sie dann auch ein passendes UI erstellen.

Hello,

I assume your question refers to a drive. In this case you can get the information directly from the drive by using the attribute "Current position". The handling of this

take place in your own C# script which you attach as a component to the game object where you need the information.

Game4Automation is an open and extensible platform. We have interfaces to many different tools. I'm sorry, but we can't afford to buy all the different tools available on the market and always upgrade to the latest version. So your support is very much appreciated.

Hi, I am sorry we just have PLCSIMAdvanced3.0. Are you able to downgrad to this version? Thanks.

Hi, I am not able to run the test server. Even if the path in your bat file is changed to our path. I am sorry we are not Python experts. Can you send it in a way so it is for sure running on our computer without any special Python configuration need?

Best regards

Thomas

Hello,

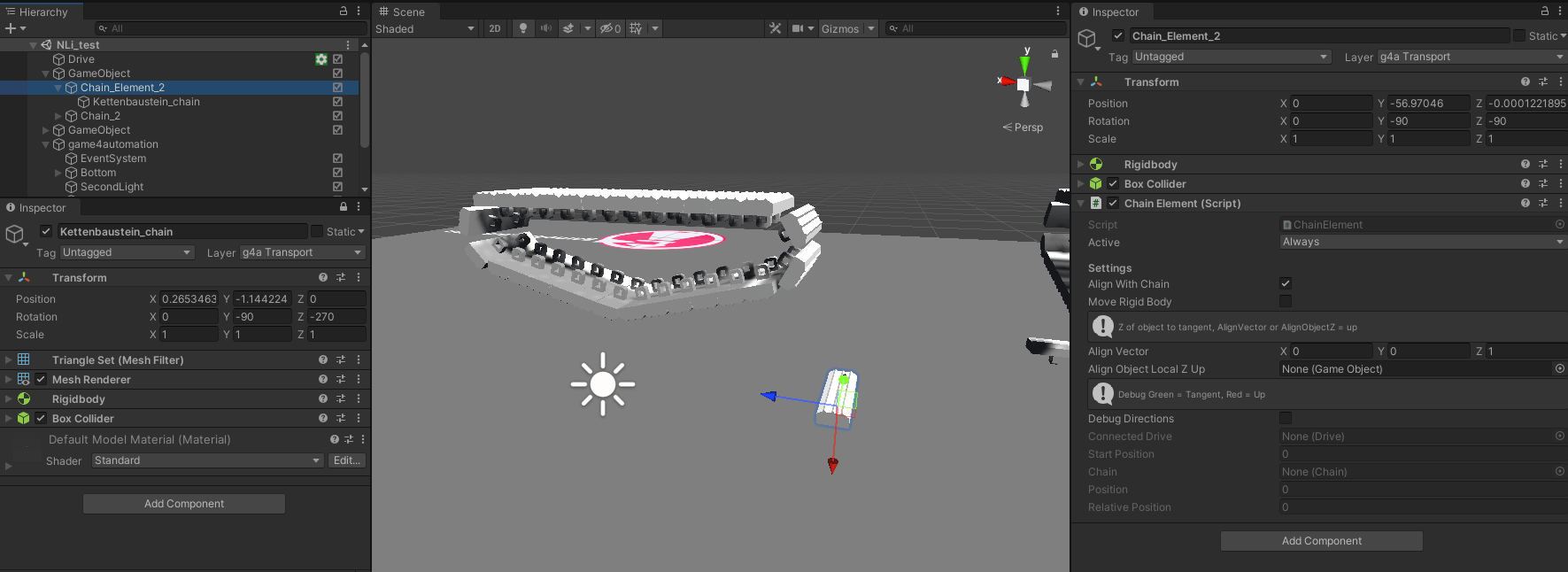

when you rotate the chain, the tangents used also change. This means that you have to adjust both the parameters of the chain element and the rotation within the chain element. To change the rotation of the two elements, proceed as follows:

Bring both elements to one level in the hierarchy.

Rotate both elements to the correct position.

Move the mesh element (Kettenbaustein) back under the chain element in the hierarchy.

Below you will find the settings for the chain element and the mesh element used.

Hi,

can you share your PLCSIM-Advanced project (PLCSIMAdvanced 3.0)? Can be a simlified one with just the inputs and outputs.

Thanks

I will add this in one of the next release. For Words you need to write a 9 as Type ID.

Can you send us your example and we will check it.

Customer support service by UserEcho

... and if you need a pulse encoder - sending pules every xxx millimeters, this will be available in one of the next releases. If you are a customer and purchased a professional version - please send us an email to info@game4automation.com with your Invoice and we can send you a beta of the pulse encoder.