Teilen Sie Ihre Erfahrunge und Wünsche mit uns und anderen Usern!

Teilen Sie Ihre Erfahrunge und Wünsche mit uns und anderen Usern!

Found bug in MeasureRaycast.cs

Found bug in MeasureRaycast.cs

I found and fixed a bug in the MeasureRaycast.cs script. Originally the "Raycast to Layer" setting would not work. I replaced the following lines.

layermask |= (1 << LayerMask.NameToLayer("RayCastToLayer"));

layermask = ~layermask;

With this

layermask = 1 << LayerMask.NameToLayer(RayCastToLayer);

And it seems to work now. Just posting for others in case they have the same issue.

You are right - thanks a lot for reporting. Will be fixed in next release.

OPC UA PLC RECONNECT

OPC UA PLC RECONNECT

If the PLC is disconnected, the application hangs/crashes.

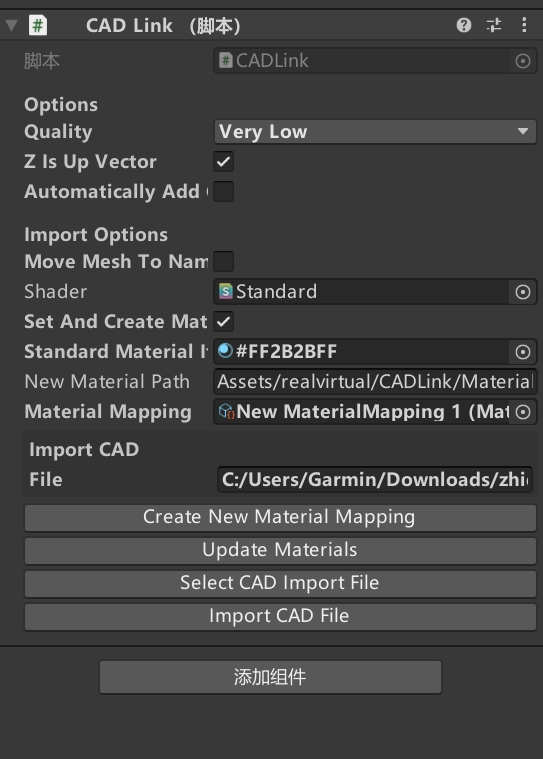

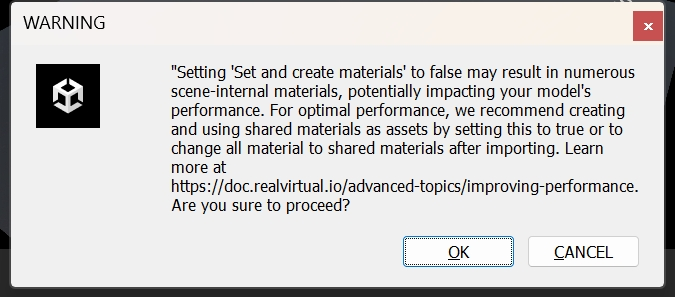

Regarding the issue of importing step from CADLINK

Regarding the issue of importing step from CADLINK

When importing step using CADLINK, "Set and create materials" has been clearly checked. However, after clicking "Import CAD File", this prompt still pops up. If the import continues, the program will crash.

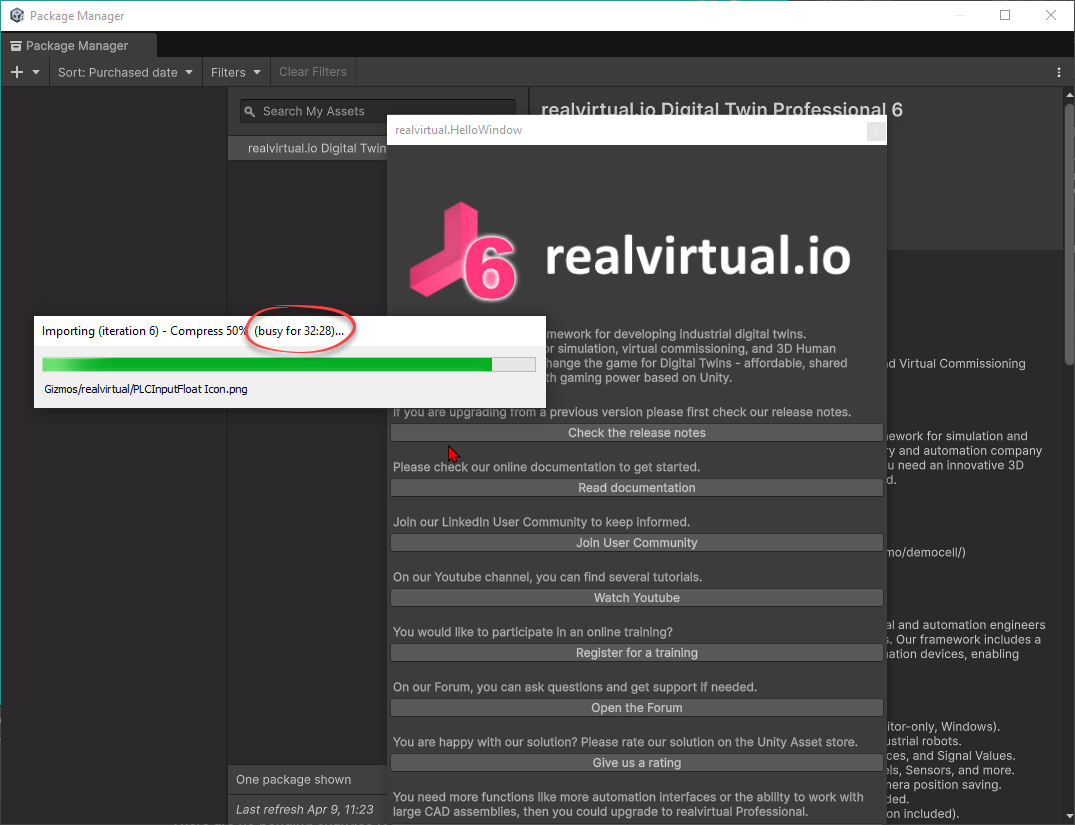

Installation hangs on PLCInputFloat Icon.png

Installation hangs on PLCInputFloat Icon.png

When installing RealVirtual Pro from Package Manager the installation hangs on PLCInputFloat Icon.png when the HelloWindow appears. If I close the HelloWindow the installation continues.

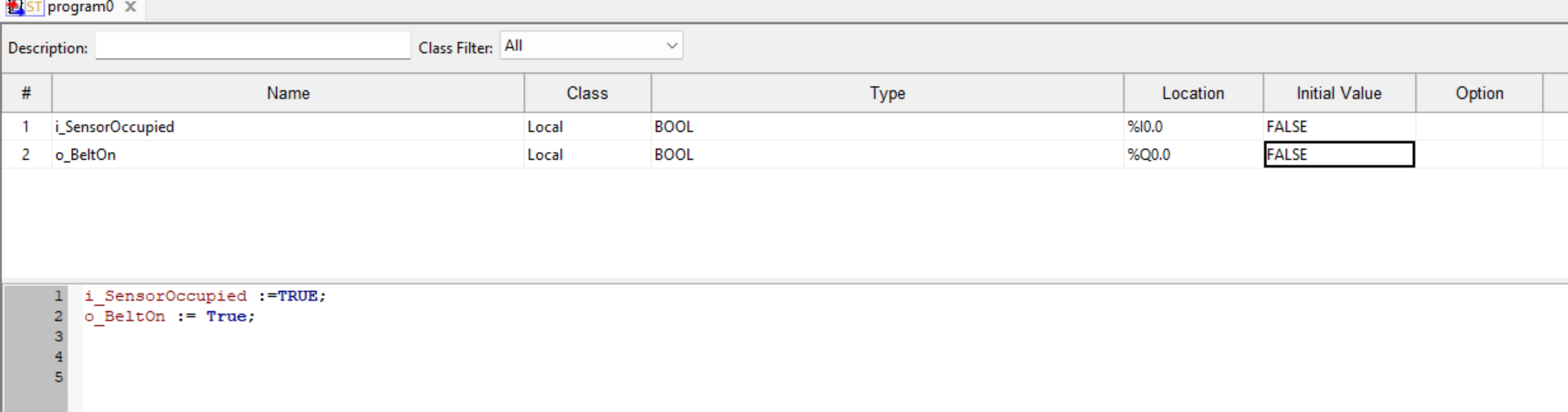

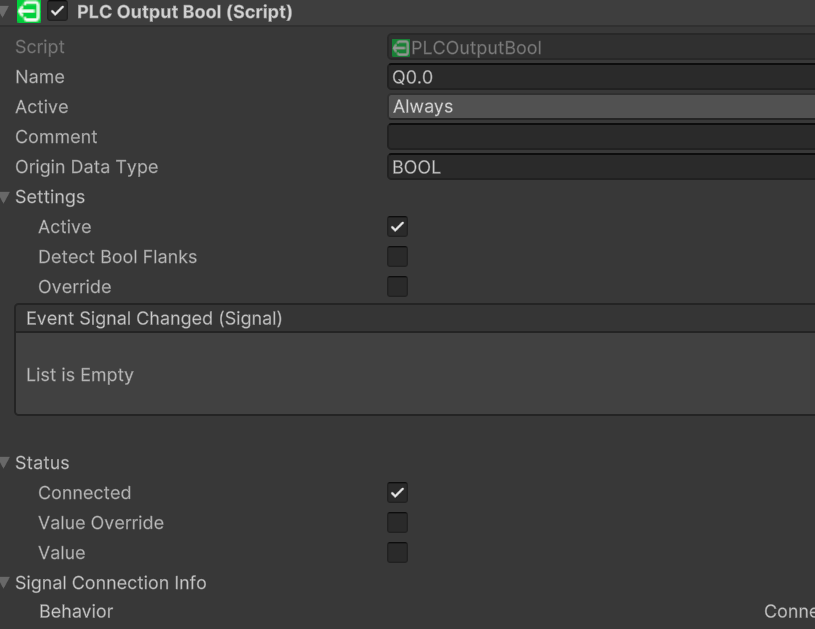

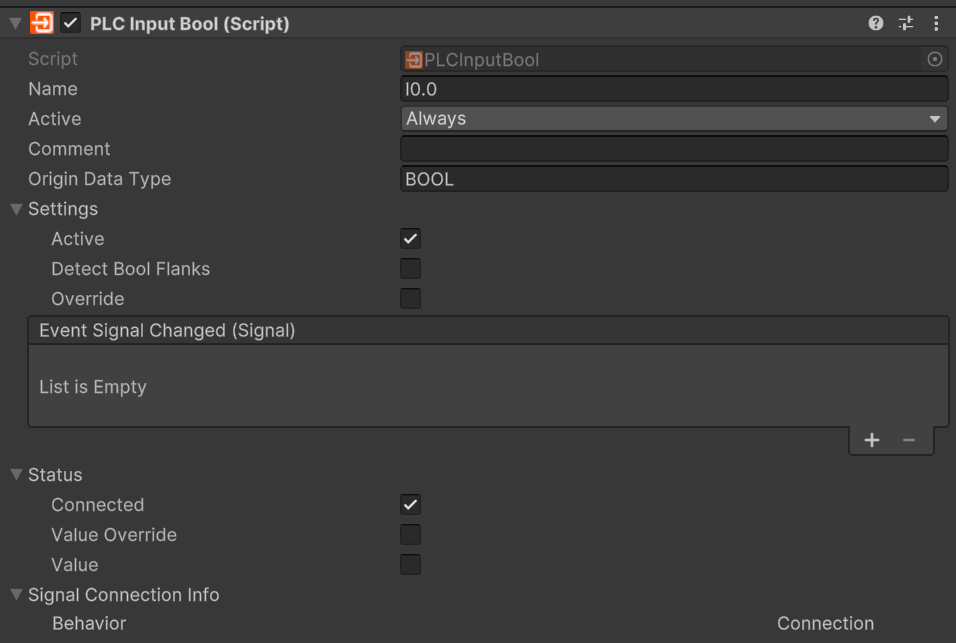

PLC Input an PLC Output are disabled when pressing play

PLC Input an PLC Output are disabled when pressing play

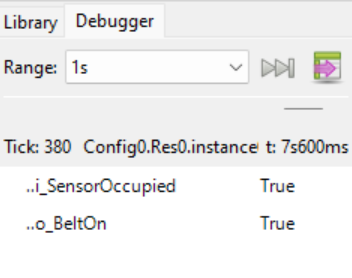

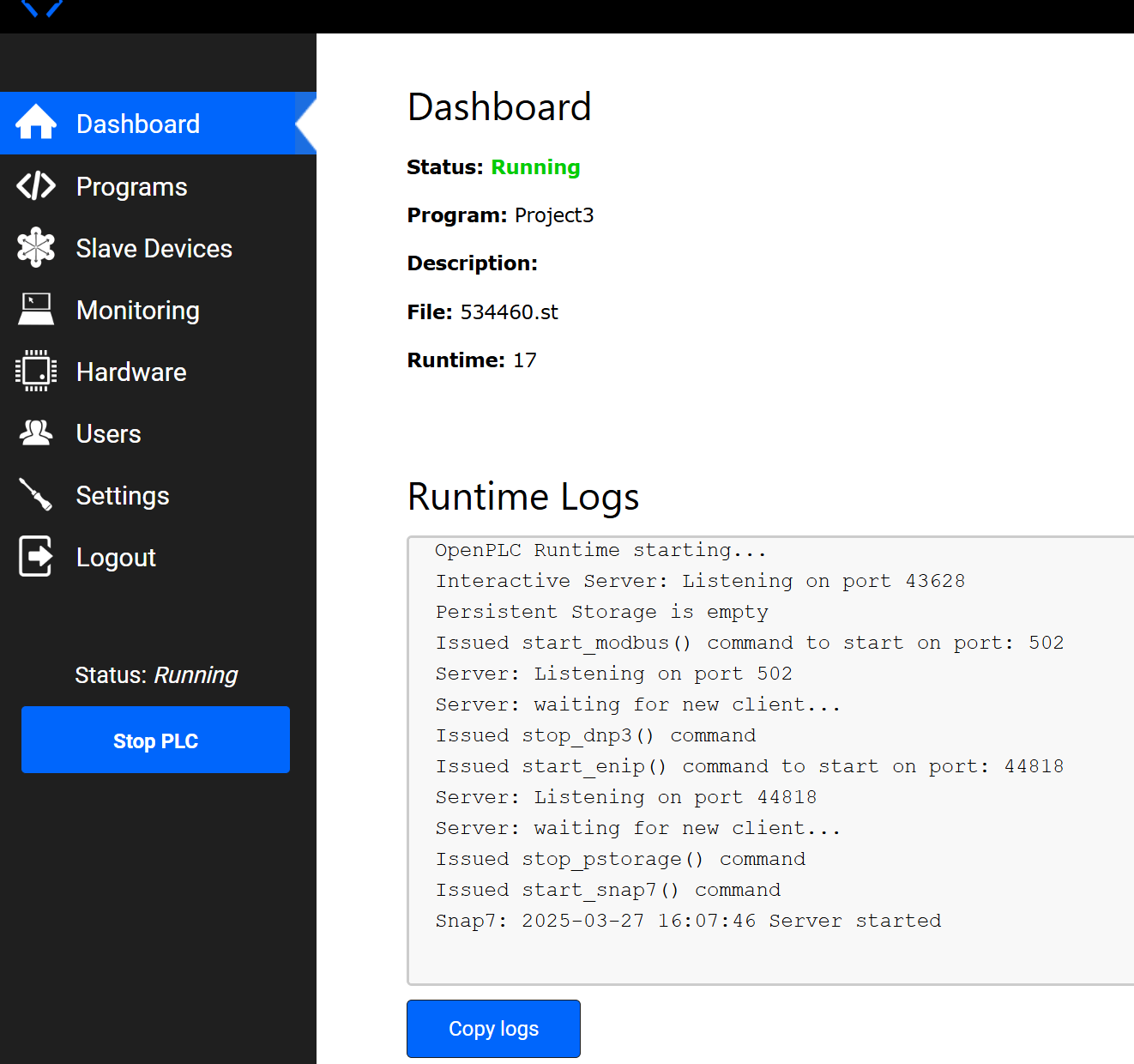

I use RealVirtual starter. I have added the S7Interface to my Unity project. I have created a softplc with OpenPLC with a very simple program

When I run it it works: values become true.

I compiled it to a runtime that also works.

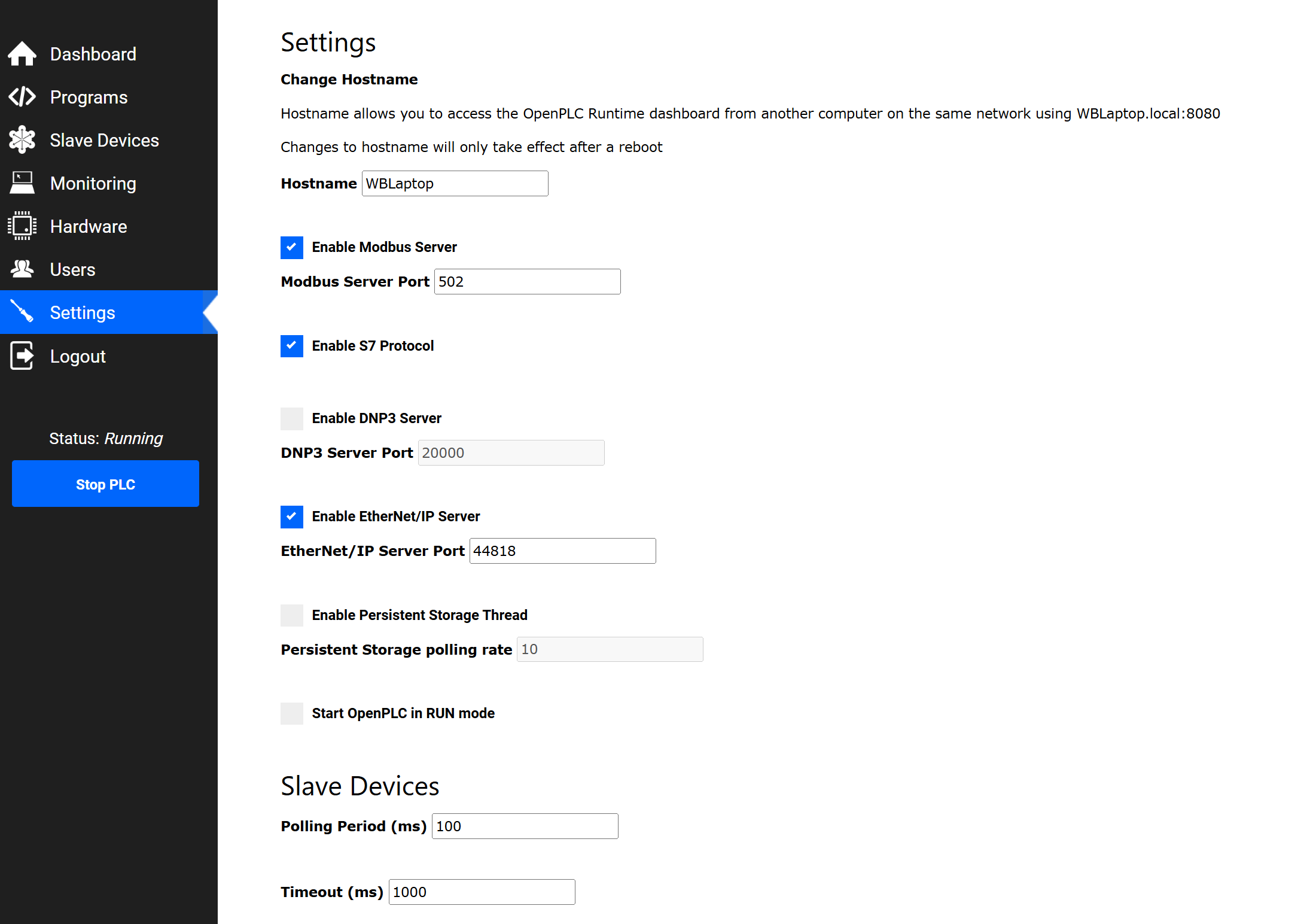

I have switched on S7 protocol for the softPLC

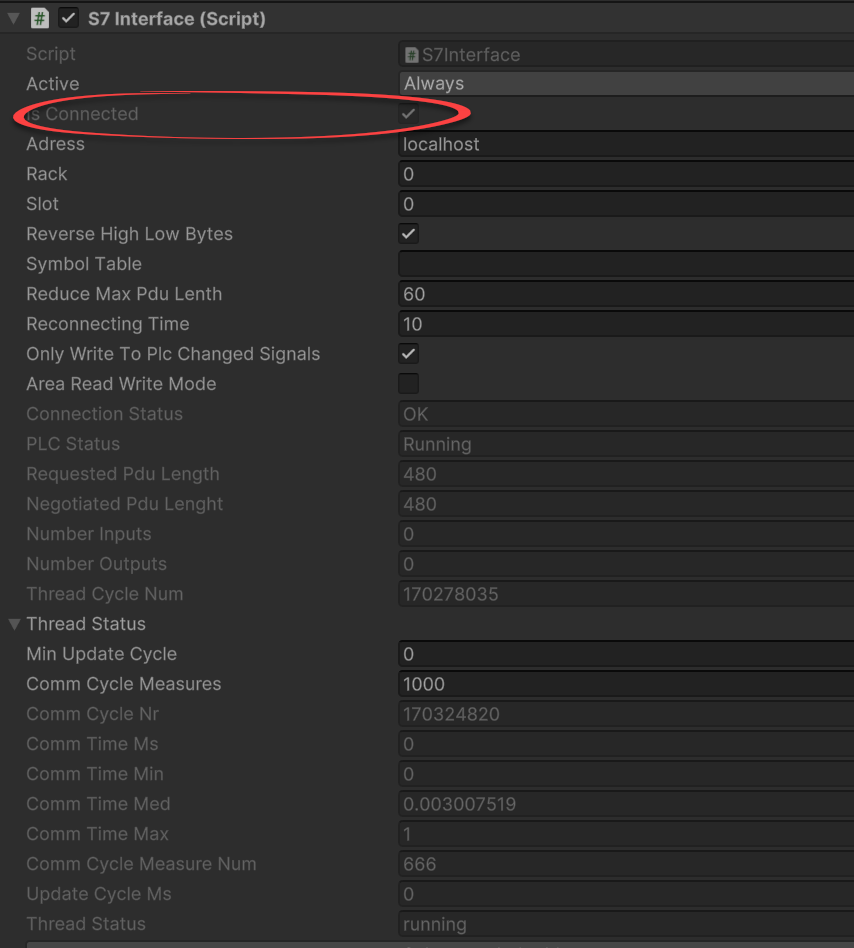

I can connect from Unity to the softplc

I have added the two signals to Unity

When I press Play in Unity the connection is made to the softPLC butboth PLC scripts are disabled.

Why is this ?

Transport Surface - Issue with "Change Constraints on Enter / Exit"

Transport Surface - Issue with "Change Constraints on Enter / Exit"

I am having difficulty with changing constraints on enter/exit of a transport surface. I get the following errors in runtime.

NullReferenceException: Object reference not set to an instance of an object

realvirtual.TransportsurfaceCollider.OnCollisionEnter (UnityEngine.Collision other) (at Assets/realvirtual/TransportsurfaceCollider.cs:29)

UnityEngine.Physics:OnSceneContact(PhysicsScene, IntPtr, Int32)

NullReferenceException: Object reference not set to an instance of an object

realvirtual.TransportsurfaceCollider.OnCollisionExit (UnityEngine.Collision other) (at Assets/realvirtual/TransportsurfaceCollider.cs:41)

UnityEngine.Physics:OnSceneContact(PhysicsScene, IntPtr, Int32)

Now for the strange part, the transport surface IS correctly setting the constraint on enter (Freeze position x in my case), but this constraint does not get removed on exit. I do have "Change constraints on exit" set to true and "none" set for the constraints exit. In the "Loaded Part" list in the transport surface, there are no objects listed in runtime even though there are game objects on the transport surface.

Has anyone else ran into this issue before? Seems weird that I am getting that error on enter, but the constraint is still getting set correctly.

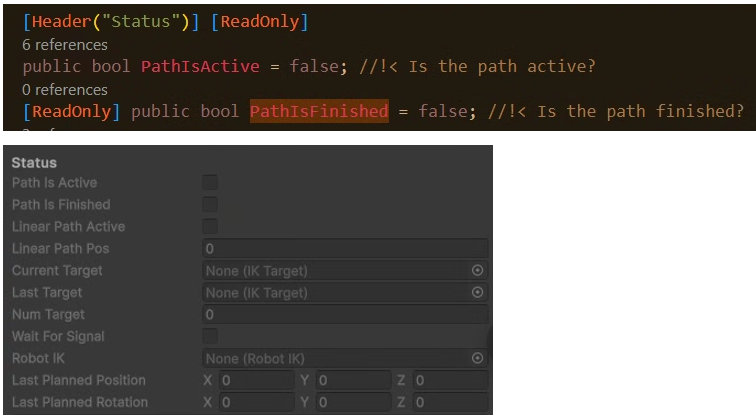

How to tell wether a Path finished?

How to tell wether a Path finished?

Hello,

I am currently working on a script that allows me to program linear movement (7th axis) for an IK robot between IKPaths. The script starts a drive destination after a Boolean is set or when a path has finished. After the linear movement, it either sets a signal or starts another path. Everything is working fine, but to check whether an IKPath has finished, I would like to use something like IKPath.PathIsFinished. However, this value does not seem to be set anywhere, even though it appears in the status bar of the IKPath inspector window.

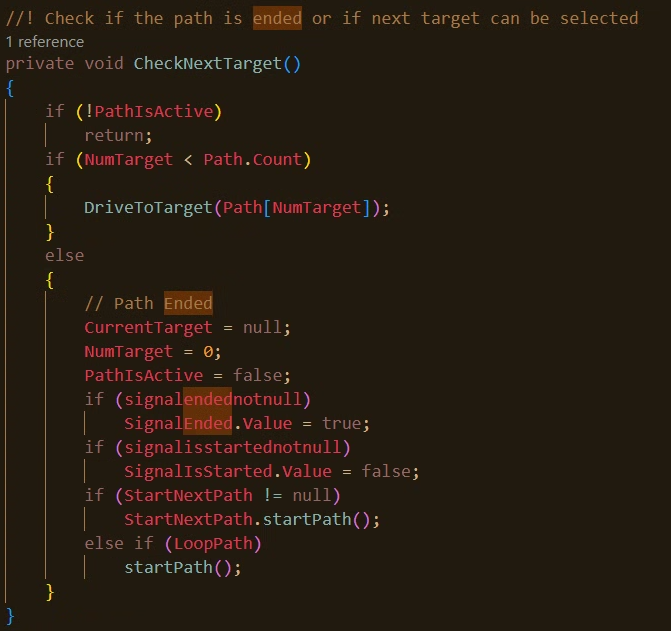

I considered adding a line to the CheckNextTarget function, but ideally, I would prefer not to modify the realVirtual scripts directly:

Is this a bug? The value should be set somewhere...

Best regards,

Nico

Questions about Modbus TCP connection to Siemens 200smart

Questions about Modbus TCP connection to Siemens 200smart

May I ask if your company has launched the modbus client access function? I need to enter an IP and PORT to access Siemens 200smart PLC.

Guided MUs not rotating on Guided transports in Unity 6

Guided MUs not rotating on Guided transports in Unity 6

After upgrading to Unity 6 LTS, the MUs are no longer rotating on turn surfaces while following a Guided Transport, however if I go back to unity 2022 it is working as intended, what could be causing this?

Senden Sie uns Ihr Feedback

Wir hören zu und setzen Ihre Ideen um.

Guided MUs not rotating on Guided transports in Unity 6

Guided MUs not rotating on Guided transports in Unity 6

S7 Interface 100% CPU when no connection to PLC is available

S7 Interface 100% CPU when no connection to PLC is available

PLC Input an PLC Output are disabled when pressing play

PLC Input an PLC Output are disabled when pressing play

How to tell wether a Path finished?

How to tell wether a Path finished?